Medical device packaging may seem like a straightforward aspect of the healthcare product lifecycle, but it is a critical part of patient safety and regulatory compliance. For medical device manufacturers, ensuring the integrity of packaging is paramount essential—yet packaging-related issues continue to surface, posing potential risks to the products and those who use them. We’ll address some of the most common problems with medical device packaging and offer insights into preventing them.

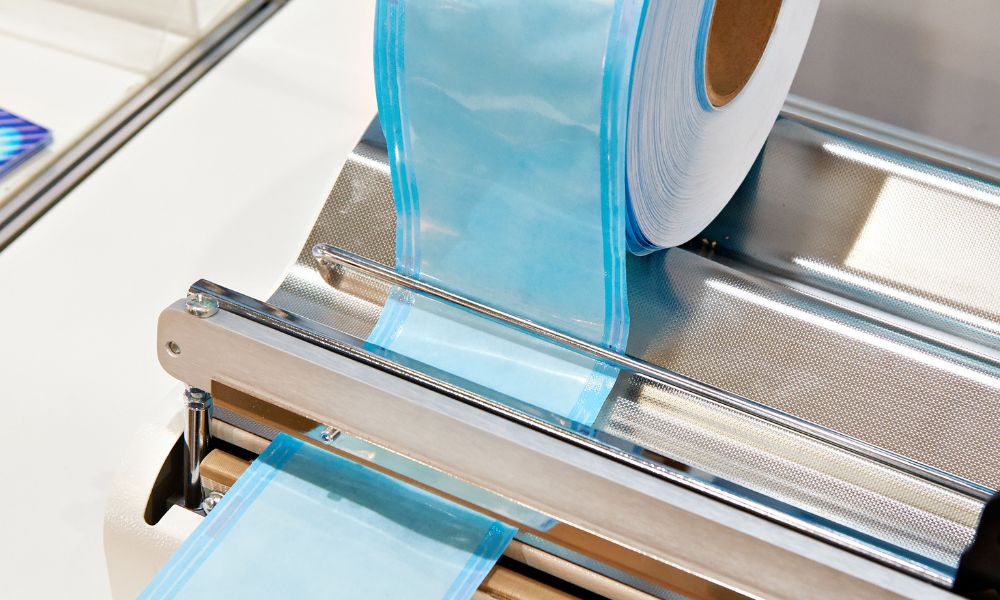

Weak Seals and Leaks

Weak seals and leaks are among the top issues that plague medical device packaging. These problems can lead to microbial contamination, resulting in the compromise of sterile contents. Leaks can also introduce elements that negatively interact with the device materials, leading to degradation or otherwise altering the device’s functionality. The causes of inadequate sealing range from inconsistent sealing pressure during the manufacturing process to contamination on heat seal surfaces. Conduct routine quality checks during the sealing process, use sealing equipment with consistently calibrated controls, and ensure that operators are well-trained and follow established protocols to help mitigate these common errors.

Labeling Errors and Omission

Packaging labeling serves as the primary communication tool for medical device usage instructions, safety precautions, and regulatory information. Any errors or omissions in labeling can have serious consequences, including misinterpretation of device usage or contraindications. Common labeling mistakes include incorrect information such as batch numbers, expiration dates, and dosage instructions. These mistakes often occur due to human error during the printing and application of labels. Therefore, implementing a robust quality management system with consistent monitoring throughout the labeling process is essential.

Noncompliant Packaging

Another common problem with medical device packaging is that it is not compliant with health and safety standards. Medical device packaging must conform to various regulatory requirements like those set by the FDA and ISO, to ensure patient safety and to pass validation and inspection. The root causes of noncompliant packaging can be anything from using incorrect materials to failing to meet specific standards for labeling, sterilization methods, or storage conditions. Consider implementing a robust change control process to manage any modification to the packaging in compliance with regulations.

Inadequate Sterilization

Inadequate or ineffective sterilization of medical device packaging systems can result in device contamination, rendering the product unsafe for patient use. Sterilization failures may occur as a result of not using the appropriate method for the specific device or failing to monitor and validate the sterilization process. To avoid this, maintain an up-to-date understanding of various sterilization methods and their applications and monitor the sterilization process with regular testing, especially after any changes to the packaging may have been made.

By addressing these medical device packaging issues, manufacturers can mitigate risks, ensure quality and compliance, and ultimately, protect the end-users of their critical healthcare products. HIGHPOWER aims to be your leading partner in ensuring your product packaging meets all appropriate standards. Our medical device package integrity testing is a step in the process for validating packaging claims, we can help to identify potential areas/causes of microbial contamination, and give you the data you need to make informed changes. Reach out to our team today to learn more.