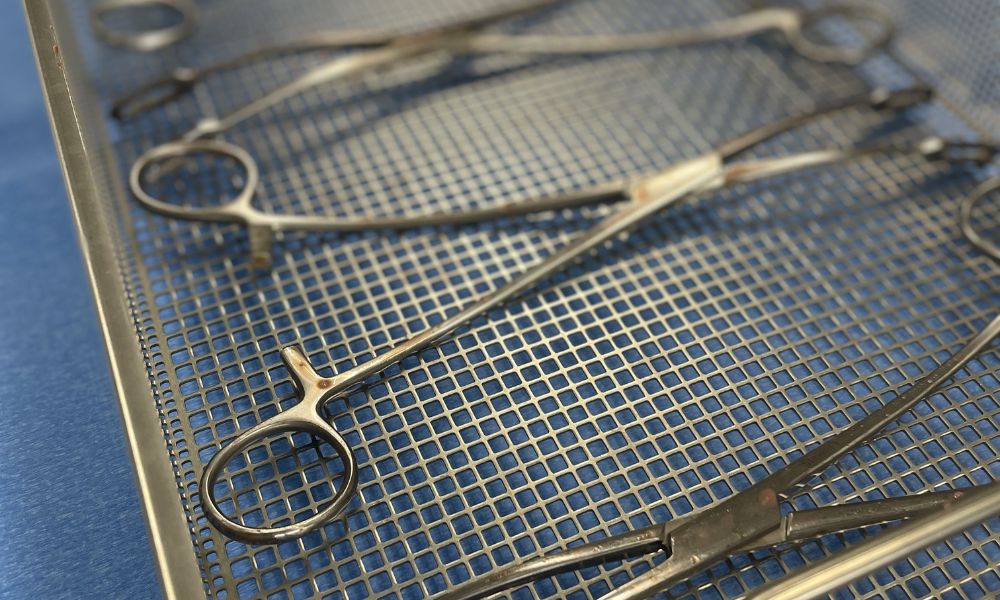

When it comes to reusable medical devices, proper cleaning between uses is essential to ensure their safety and effectiveness. However, cleaning such devices can prove to be challenging, which makes cleaning validation even more important. As you develop your product, be aware of the potential pitfalls so that you can adjust to them accordingly. We will discuss the top 4 common cleaning validation challenges for reusable medical devices and how to overcome them.

Residual Soil Buildup

Residual product buildup is one of the most common challenges in keeping your device clean through several uses. Additionally, manufacturing oils/products and clinical soils such as blood and mucus can also accumulate on your reusable device. When cleaning these devices, it is important to ensure that professionals remove all traces of soil on the device by following the manufacturer’s validated instructions for use. However, this can prove to be difficult, especially when the residue is not visible and you incorporate variables such as different hospital settings, poor training, and user error. To overcome this challenge, establish sensitive testing methods to measure residue and validate that your cleaning process is vigorous.

Complex Device Designs

Many reusable medical devices have complex designs that make cleaning them a challenge. These designs can have areas such as lumens or screws that make it hard to properly clean. Having a thorough understanding of the device design and developing cleaning procedures that are specific to that design can help with this. This usually involves disassembling and reassembling the device during the cleaning process to ensure that all parts receive the necessary attention.

Compatibility Issues

Another common cleaning validation challenge for reusable devices is a lack of compatibility with certain cleaning materials. Some cleaning agents used during the cleaning process may not be compatible with the reusable device’s materials, which can lead to device damage, corrosion, or incomplete cleaning. This is why it is crucial to carefully select cleaning products that are compatible with the materials used in the reusable device and test that the cleaning process can be repeated multiple times throughout the device’s duration. Testing the compatibility of cleaning agents with the device and after exposure to a sterilization cycle are important during the development process to avoid compatibility issues and extend the useful life of the device.

Inadequate Validation Procedures

Above all though, inadequate validation procedures can result in incomplete cleaning and poor device performance. Make sure you establish robust validation procedures that test every aspect of the cleaning process to the most current standards. This may involve conducting testing in multiple phases of cleaning, using different cleaning agents, and testing methods (such as manual or automated cleaning), and verifying the effectiveness of the cleaning procedure. This is where a third-party independent test lab such as HIGHPOWER can be a great resource.

Ensuring the safety and effectiveness of reusable medical devices is paramount, and proper cleaning validation is a crucial step in achieving this. By understanding and addressing the common cleaning validation challenges for these devices, manufacturers can ensure that they are providing high-quality devices that meet regulatory requirements. As a leading validation laboratory serving the medical, dental, pharmaceutical, and industrial industries for over 30 years, HIGHPOWER has extensive experience in addressing the challenges presented during the cleaning validation process to ensure the manufacturer has a robust cleaning method that is effective and reproducible. Our device cleaning validation testing services are thorough, comprehensive, and performed to the most up-to-date regulatory standards. Rest assured that you will always have all the data you need when you work with us.